Shawn

Member

I started about a year ago with a pair of channel-locks, a piece of rail, a 4x36 belt "grinder" and a very bad design for a "forge".

After a few design/material modifications, acquiring a "real" anvil and a new attachment for my grinder, I'm producing some really mediocre stuff now!

I also came across a small coal forge, but haven't messed with it a lot yet.

Gas forge

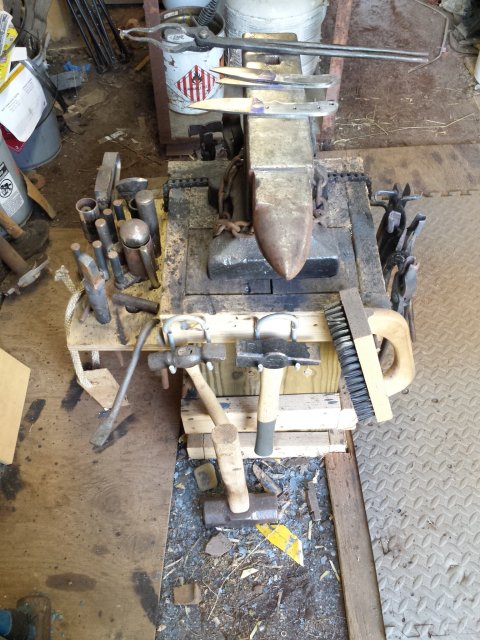

Anvil and some tooling

Belt grinder attachment that changes it to a 2x48

After a few design/material modifications, acquiring a "real" anvil and a new attachment for my grinder, I'm producing some really mediocre stuff now!

I also came across a small coal forge, but haven't messed with it a lot yet.

Gas forge

Anvil and some tooling

Belt grinder attachment that changes it to a 2x48